The proposal began with the following comment: “It is vital that TEPCO permeates safety culture throughout the entire organization — from upper management to first-line managers in the field — and aims to constantly maintain higher standards.” It went on to praise the company’s activities, while asking it to “quickly finalize” key performance indicators (KPI) for quantifying progress of the nuclear safety reform.

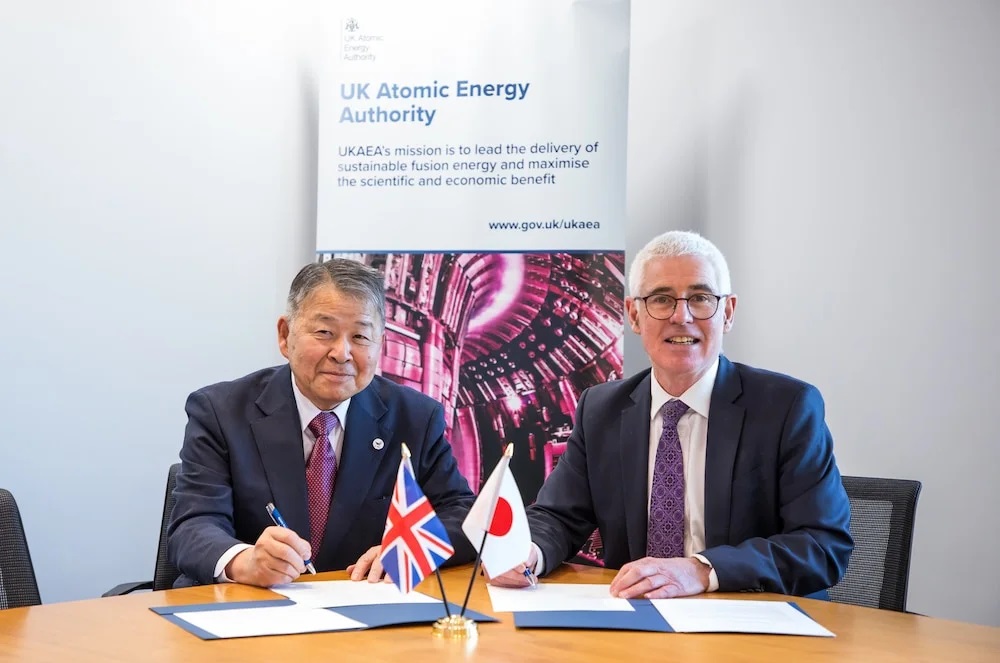

The report then moved on to the matter of communications, praising TEPCO for actively conveying information overseas on “the lessons learned from the Fukushima nuclear accident, the progress of decommissioning.”

Meanwhile, the report hailed the completion of removal of spent fuel assemblies from Fukushima Daiichi Unit 4 as a “big step forward” in the reactor’s decommissioning.

At the same time, it pointed out that the power company should strive further to implement measures to prevent the dispersion of radioactive substances, as well as to monitor mechanisms and carry out the treatment of contaminated water.

At a press conference held at TEPCO headquarters in Tokyo on the same day, committee chairman Dale Klein, who used to lead the U.S. Nuclear Regulatory Commission (NRC), announced that the committee would next meet near the site of the Kashiwazaki Kariwa Nuclear Power Station (NPS), adding that an opportunity might be arranged for residents to ask questions.

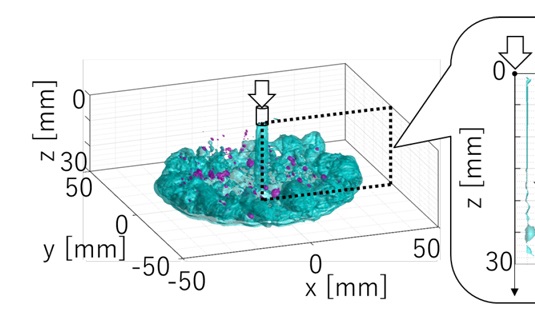

Fuel Assemblies Continue to Be Removed at Fukushima Daiichi Unit 3, with Preparations Made for Those at Unit 4

On November 27, the Agency for Natural Resources & Energy (ANRE) of Japan’s Ministry of Economy, Trade and Industry (METI) released a progress report on the decommissioning work being carried out at the Fukushima Daiichi NPS.

Currently, spent-fuel assemblies are being removed from the Unit 4 spent fuel pool, with 1,331 such assemblies already having been fully transferred to the common pool by November 5. Another 202 fuel assemblies are to be transferred to the Unit 6 spent fuel pool by the end of this month.

Debris removal at the Unit 3 spent fuel pool — suspended due to the dropping of a control console for a refueling machine into the pool — will resume later this month. To prevent similar accidents, additional panels will be installed to protect the fuel racks.

The assemblies from the Unit 3 spent fuel pool will be removed by crane, with remotely-controlled equipment handling the spent fuel. Although human workers, in principle, will not be directly entering the operating floor because of the radioactivity, they will be involved in physically installing and inspecting the equipment, as well as in dealing with various problems. Currently, the operating floor is being decontaminated, with shielding being installed.

In addition, hot tests of the multi-nuclide removal equipment — called the “Advanced Liquid Processing System” (ALPS) — are being carried out with water containing radioactive materials. The original system has already treated 171,000 cubic meters, with the additional system treating 36,000 cubic meters and the new high-performance system 3,000 cubic meters.

Improved Environment for Workers at Fukushima Daiichi

On November 27, TEPCO released the results of a survey on improvements of the work environment being carried out at the Fukushima Daiichi NPS. Materials related to the survey materials, including questionnaires, were distributed to all workers except for TEPCO employees, with responses coming from some 4,587 persons, representing about 70% of the total.

According to the survey results, more than 80% of the respondents said that TEPCO’s efforts to improve the work environment were either “good” or “not bad.” The percentage answering “good” to various questions about the current work environment was higher than the previous survey, released in December of last year.

The total percentage of survey respondents saying that the usability of the entry administration facility was either “good” or “not bad” was 77%, up ten percentage points from the year before. Similarly, 90% described measures for health management the same way, up from 81%.

Some 70% of the respondents described the usability of rest places as “good” or not bad,” marking a rise from the previous year’s 58%. As for their opinion of the environment of workplaces on NPS premises, some 69% said it was “good” or “not bad,” up sharply from the 44% recorded one year ago. Also, 58% described the environment for eating at Fukushima Daiichi as “good” or “not bad,” up from 40%.

Meanwhile, unfavorable comments (i.e., those replying “not good” or “not very good” in the survey) were made about the following points, indicating room for improvement:

- There are not enough parking spaces on the NPS premises.

- There are not enough lockers at the entry administration facility.

- There is insufficient bus service, and the buses that do run are crowded.

- All the places provided for resting and relaxation are too small.

- The roads on the NPS premises are in bad condition.

- Having to wear a whole-face mask makes it hard to see and hear.

- You have to buy or bring your own lunch.

- There is no place to dump food trash.

Meanwhile, almost half the respondents — some 47% — said that they felt that working at Fukushima Daiichi was “rewarding” or “somewhat rewarding,” with most citing Fukushima’s reconstruction and decommissioning as their reasons for feeling that way. In contrast, only 14.2% said that their work was not so rewarding, or not rewarding at all, with the remaining 30.4% saying that they could not give an answer.

As for their worries about working at Fukushima Daiichi, almost half of the respondents — 49.7% — said that they did not feel any anxiety, slightly surpassing the 43.7% of those who said that they did feel that way. When asked about their families’ feelings about their working at the reactor, however, more than half — 55.1% — said that their families felt anxiety about their work, significantly exceeding the 37.2% who answered conversely. The most frequently cited reason for the families’ anxiety was the fear of bodily effects of radiation exposure.