ATF is a promising means to those ends, and progress toward commercialization is being seen, particularly overseas. For example, the experimental loading of ATF is already being carried out the United States. Meanwhile, a draft approved by the European Commission (EC) in February treats the loading of ATF for nuclear power by 2025 is a “compatible condition” in the EU taxonomy, which is kind of a “green list” providing technical screening criteria for recognizing economic activities as contributing to sustainability, in the mitigation of climate change.

In light of such developments elsewhere in the world, the Japan Atomic Energy Agency (JAEA) and the Graduate School of Engineering of the University of Tokyo have been engaged in ATF research and development projects commissioned by the Agency for Natural Resources and Energy (ANRE) and the Ministry of Education, Culture, Sports, Science and Technology (MEXT).

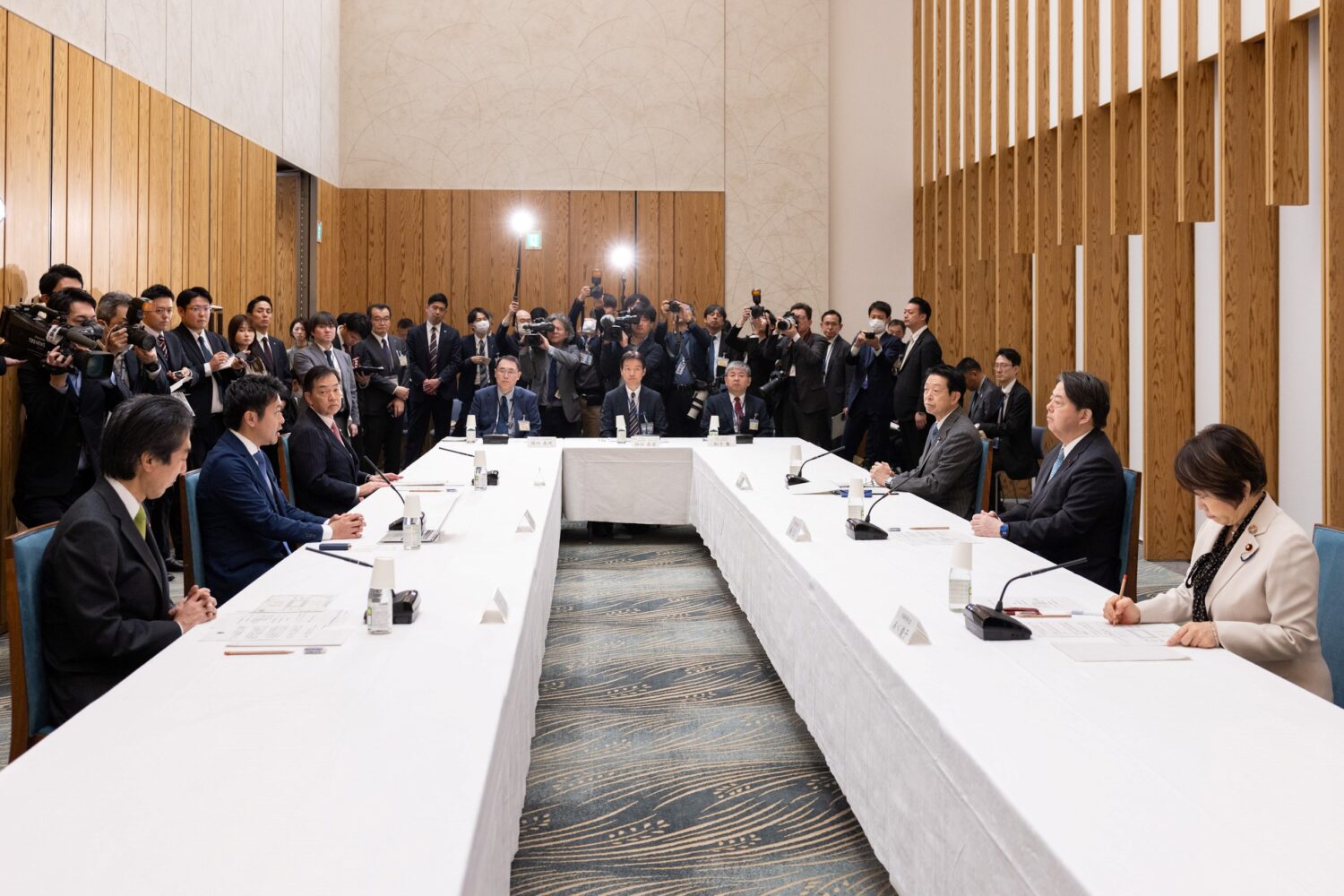

On March 11, they held an online technological workshop on the development of ATF for LWRs. Called “Enhancing Nuclear Safety through Advanced Domestic Reactor Fuel with High Tolerance to Accidents,” the workshop had approximately 230 participants.

Major domestic manufacturers in Japan have developed ATFs, including coated cladding tubes, improved stainless steel cladding tubes, silicon carbide cladding tubes and accident tolerant control rods, but issues have persisted that must be resolved before commercialization, including the brittleness of materials and the insufficient accumulation of data.

The development of coated cladding tubes by Mitsubishi Heavy Industries (MHI) and others is the furthest along, and commercialization is expected during the early 2030s. In that form of ATF, the surface of the cladding is coated with chromium to enhance oxidation resistance and suppress the generation of hydrogen.

At the March 11 workshop, Professor ABE Hiroaki of the Graduate School of Engineering at the University of Tokyo and YAMASHITA Shinichiro of JAEA’s Nuclear Science and Engineering Center each gave presentations on the status of development at their respective institutions.

Prof. Abe compared Japan’s technology readiness level (TRL) with that of other countries, from the demonstration of principle to commercialization, while JAEA’s Yamashita looked at the development history from 2015 and the development of element technology by the private sector. Together, they illustrated the importance of strengthening domestic and international cooperation systems.

In the subsequent panel discussion, the two speakers were joined by SUGIYAMA Tomoyuki of Japan’s Nuclear Safety Research Center (NSRC) and SATO Daiki from the Mitsubishi Nuclear Fuel Company to discuss the challenges involved in introducing ATF in Japan.

From his position of being engaged in the development of core manufacturing technology at a research institute, JAEA’s Yamashita stated his worries about the limited facilities available to carry out testing in Japan. He also emphasized the need to effectively use test data obtained at research reactors overseas.

Meanwhile, NSRC’s Sugiyama, discussing support for companies within the regulatory sphere, said, “ATF is an important technology that can affect such things as the safety evaluations of nuclear reactor facilities, risk assessments, equipment designs, the designing of reactors to be newly built, and disaster prevention plans.”

As a member of the Reactor Core Fuel Subcommittee of the Atomic Energy Society of Japan (AESJ), Mitsubishi Nuclear Fuel’s Sato talked about the activities of three technical working groups addressing ATF.

University of Tokyo Prof. Abe, who serves as chairman of the subcommittee, stressed his group’s attitude of addressing questions scientifically and technologically, and saw the possibility that companies’ business judgments might complicate the introduction of new technology. He implied that comprehensive understanding would be necessary among manufacturers, users and regulators.

At the same time, some workshop participants pointed out other economic and secondary benefits from introducing ATF, including improved response margins when an accident occurs, and shorter periodic inspections as a result of lengthened lives of control rods.

In our interview with KAWANISHI Tomohiro of JAEA’s Research LWR and Promotion Office concerning the topic of staging the workshop, he said, “ATF could be procured from the United States, whose development in the field is ahead of us, simply from the point of view of short-term economic rationality. But domestic development is called for in terms of maintaining and ensuring the technological foundations and human resources for the medium and long term.”

-1.png)

.jpg)