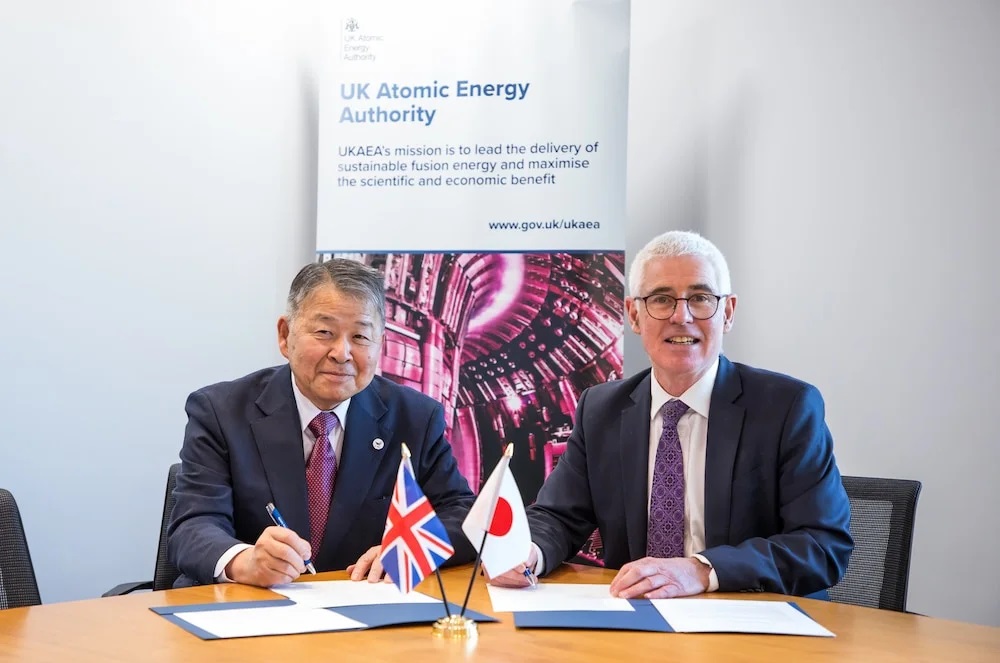

With plans to use the Naraha Remote Technology Development Center now being constructed by JAEA in Fukushima Prefecture — and which will begin full operation in FY16 (starting in April 2016) — the three parties will cooperate in research on technology for removing fuel debris as part of the decommissioning process at the Fukushima Daiichi NPPs.

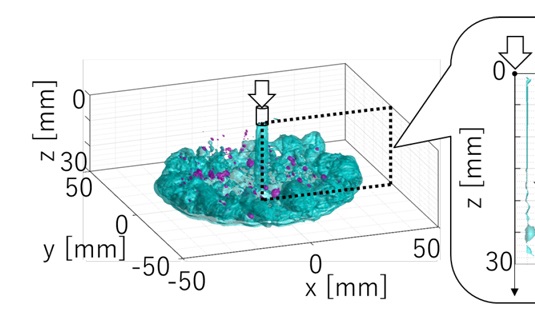

At Fukushima Daiichi, remotely-controlled equipment and devices must be inserted into narrow places to remove fuel debris and core internals in a controlled, stable manner. With laser-beam machining methods adapted to that challenge, high-energy beams can be projected with microscopic precision, minimizing the thermally-affected areas. Equipment and devices can also be miniaturized.

Having developed laser-cutting technology that enables the amount of secondary waste to be reduced, and which allows work in narrow spaces by remote control, JAEA has been successfully investigating the cutting characteristics of thick steel plates in underwater environments at the advanced thermal reactor (ATR) known as “Fugen.”

Hitachi-GE, a major BWR vendor, is currently developing technology for decommissioning and decontaminating the Fukushima Daiichi. Sugino Machine, meanwhile, is developing remotely-controlled equipment and devices that can operate in highly-radioactive environments (see photo).

Under the joint research agreement, the three parties will apply their mutually complementary expertise in cooperative basic research to develop new methods of processing, cutting methods within reactors, and the cutting of thick steel plates. All those techniques will be used in the application of laser technology to the decommissioning of the Fukushima Daiichi.