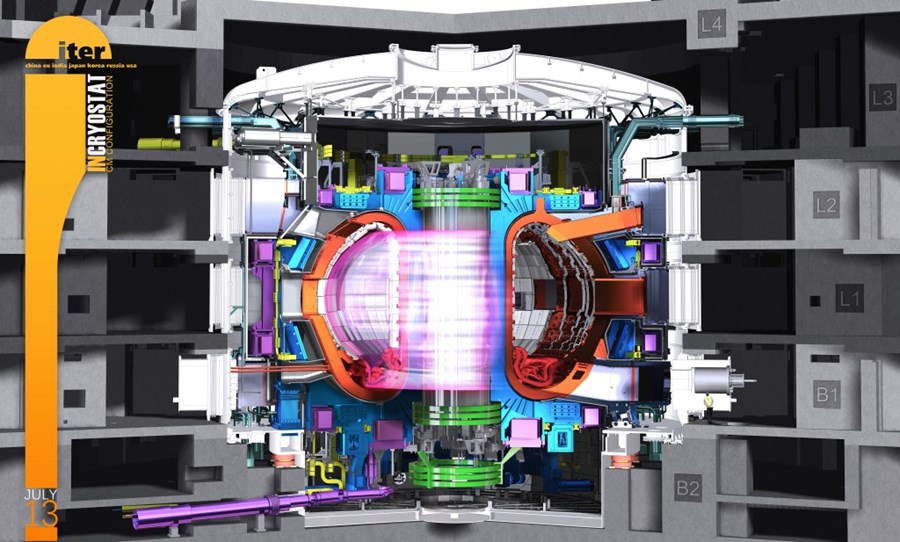

The claim was that the steel in the JCFC-made products was too weak for use in NPP safety-related systems.

On November 22, however, at a regular meeting of Japan’s Nuclear Regulation Authority (NRA), it was determined that it was “unlikely that any of the products” used by eleven domestic power companies in their plants “contained carbon concentrations higher than prescribed limits” for safety-related systems.

The NRA thus concluded that there was no possibility of “weaker-than-expected performance” of such products in any domestic NPP.

The NRA found that JCFC adequately slices off those parts of its steel ingots (used to then make its products) that contain high concentrations of carbon, a cause of insufficient strength. Accordingly, it determined that the products in question were sufficiently strong, using the phrase, “no shortage of strength.”

It also evaluated and came to the same conclusion for NPP safety-related systems produced by other domestic manufacturers, including Japan Steel Works, Ltd. (JSW).

According to reports from the power utilities, JCFC manufactured vessel heads for eleven NPPs at seven NPP sites, including Takahama-2, owned and operated by the Kansai Electric Power Co. (Kansai EP), and two NPPs that are slated to be commissioned, namely, Kansai EP’s Mihama-2, as well as Genkai-1, owned and operated by the Kyushu Electric Power Co. No problems were found at any of those reactors.

That resolves the issue of “carbon segregation” at domestic NPPs for the time being. The NRA will, however, further pursue issues of product quality involving the homogeneity of chemical components in forged steel products, including gathering relevant information.

-1.png)

.jpg)