On December 19, the Tokyo Electric Power Co. (TEPCO) announced that it had decided on a method to remove fuel from the spent fuel pool at the Fukushima Daiichi-1 Nuclear Power Plant (NPP) by installing a large cover first, then removing the debris from under the cover.

Besides that method, the power utility had been considering another in which debris would be removed first, after which the cover would be installed and the fuel removed under the cover. TEPCO made its decision after comprehensively evaluating dust-suppression measures, radiation exposure to workers, rainwater measures (the generation of contaminated water), and the effects on surrounding work operations.

A total of one hundred unused fuel assemblies and 292 spent assemblies are being stored at the Unit 1 spent fuel pool. After the removal of the debris, the fuel will be removed using a 360-ton overhead crane, all under a large cover measuring about 65m high, which will enclose the entire reactor building.

At a press conference on the same day, President Akira Ono of the Fukushima Daiichi Decontamination & Decommissioning Engineering Company underscored the company’s commitment to carrying out the work with top priority on safety, saying, “As residents are increasingly returning to their homes in Okuma, the debris removal will be carried out even more carefully.”

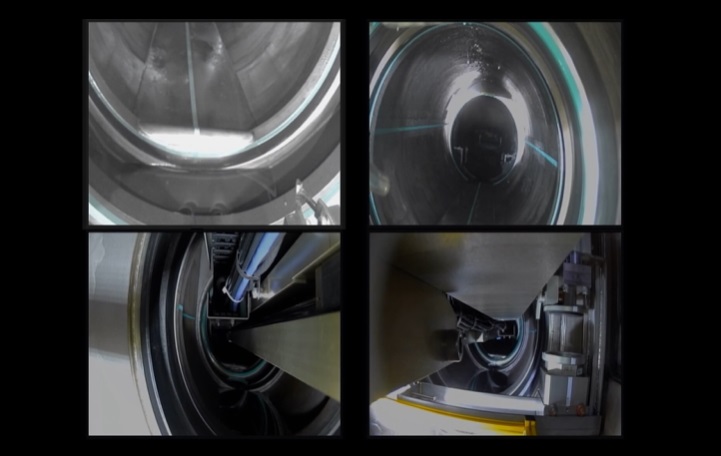

TEPCO regularly releases videos to the public showing progress on the removal of the fuel from the Unit 1 spent fuel pool.

According to the current “mid-to-long-term roadmap” toward the decommissioning, the fuel is to be removed from the Unit 1 spent fuel pool in FY23, which begins in April 2023. A revised draft of the roadmap, proposed on December 2 at a meeting of the Contaminated Water and Decommissioning Issues Team, chaired by the head of the Ministry of Economy, Trade and Industry (METI), shows that the fuel will be removed from the spent fuel pools at all the units on the site by the end of FY31 (namely, March 31, 2032).

Turning to Unit 2, where removal of fuel debris is slated to begin, Ono referred to a series of investigations carried out inside the reactor containment vessel in February 2019, adding that the most significant finding had been that the debris could, in fact, be moved.

Citing a trial removal of a small amount that will be carried out afterwards, he said, “Removal on the order of several grams will be repeated several times. It is important to determine the actual hardness.” His implication was that the appropriate tools would then be developed for the full-scale removal.

A robot arm extendable to a maximum of 22m, for use in the trial removals, is being manufactured in England.

Reflecting on problems that have occurred with the fuel handling equipment at Unit 3 and elsewhere, Ono said that those had been bitter experiences.” He reiterated the importance of steady inspections, maintenance and training.