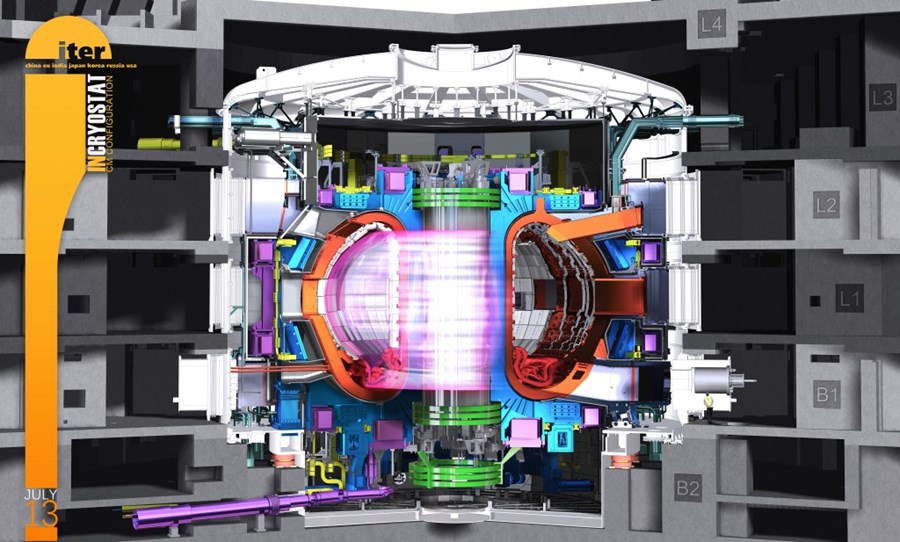

In nuclear fusion, tritium concentrated to high purity is used as fuel. Tritium is, however, radioactive, and must be removed from exhaust gases to prevent adverse effects on the public and the environment. ITER had initially adopted the drying tower method, wherein tritium in exhaust gases is oxidized into water vapor. It was found, however, that the continuous use of three drying towers increased the risk of failure of equipment because of frequent valve operations. Accordingly, QST sought to develop a new system using scrubber towers, which are used to remove dust and soot, odors, and the like from exhaust gases at factories and wastewater disposal facilities.

Tritium removal using a scrubber tower involves a simple structure with simplified operations and reduced failure risk, spraying pure water into the tower with special packing inside and continuously washing away the steam including the tritium. Although there was concern that the new system would increase ITER’s wastewater volumes in comparison with the conventional drying-tower method, QST overcame that problem by improving the properties of the chemical packing.

During the course of some 11 years―including the period when the former Japan Atomic Energy Research Institute (JAERI) was responsible for nuclear fusion development in Japan―QST has been engaged in the reliability verification of tritium removal using scrubber towers.

The result is that no decline in performance due to aging has been seen through a decade of continuous operation―thus verifying that the system will maintain long-term integrity as a means of tritium removal effective to promote the ITER project.

The QST research team engaged in the technical development said, “This technology will not only improve ITER safety but will also greatly contribute to Japan’s development of a prototype reactor.”

-1.png)