The completed prototype is a J-shaped full-scale mockup of the OVT, measuring about 1.5m high and about 60cm wide. MHI and QST have been engaged in its production since 2020.

MHI is already involved in producing 18 of the 58 OVT units (including backups) that QST will eventually deliver to ITER (it was QST that had originally placed the order for them from MHI). The company plans to deliver six of the units next year (2025). With the completion of the prototype, MHI is ready to mass-produce the remaining units.

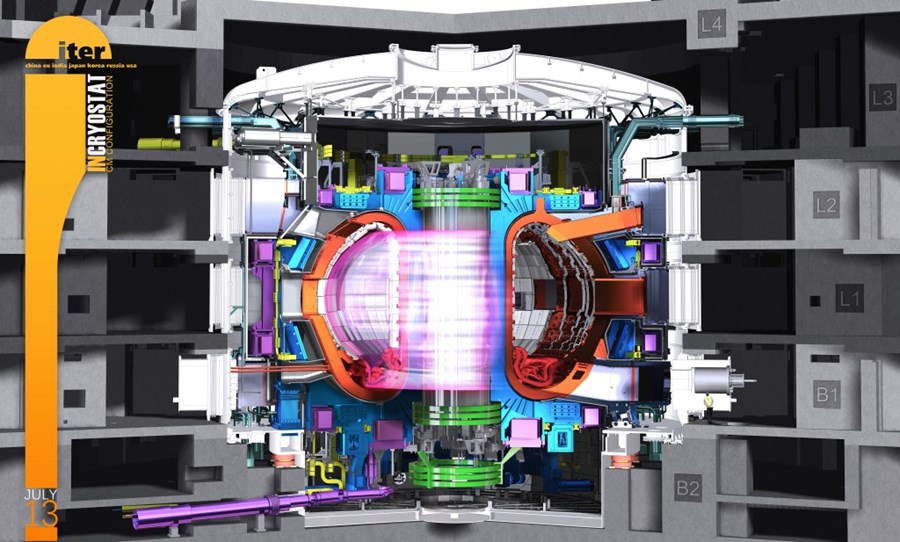

The heat load on a divertor target can reach as high as 20MW/m², equivalent to the surface thermal load on an unmanned asteroid probe during re-entry into the Earth’s atmosphere, and approximately 30 times the surface thermal load on the manned Space Shuttle.

The environment for divertors used in tokamak devices is deemed “extremely severe.” Because of such an extreme thermal environment, divertors must contain special materials such as tungsten, which has a high melting point but is difficult to machine.

In principle, each member party of the ITER project makes contributions in kind: Japan has received orders to produce the divertor’s OVTs, while the European Union (EU) is in charge of making the IVTs (internal vertical targets).

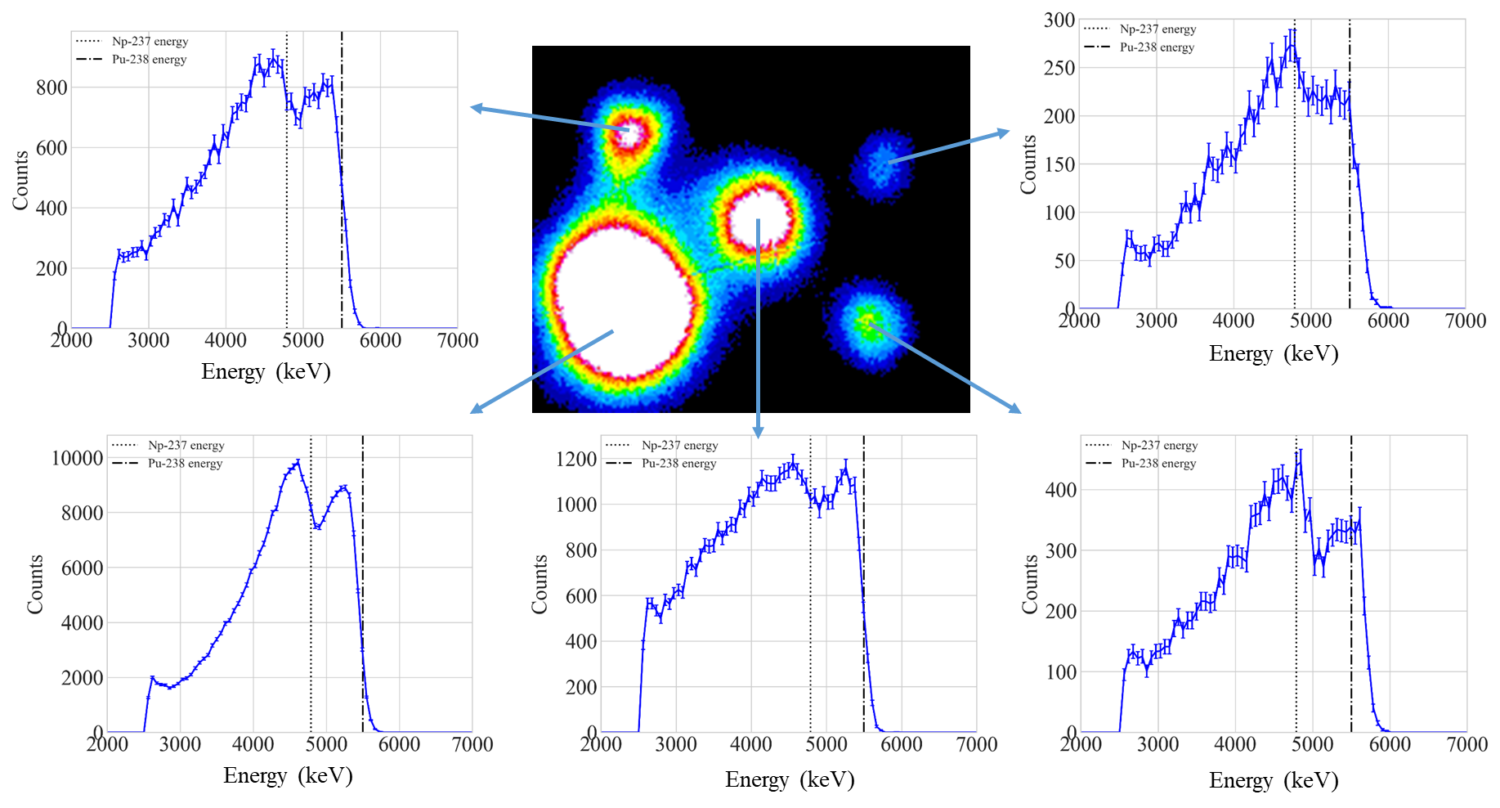

An OVT is composed of tungsten blocks with dimensions of about 30mm x 30mm x 10mm, with each divertor unit requiring more than 3,000 such blocks. As the failure (melting) of any one of them could cause a major problem, the technological requirements for the tungsten blocks are strict.

As part of the effort to create a suitable substance, MHI developed a tungsten material durable at high temperatures, featuring cooling pipes made of a Cr-Zr-Cu (chromium-zirconium-copper) alloy to cool the material, and a “brazed bonding” heat treatment to join the materials, thereby overcoming the challenges of durability at ultra-high temperatures.

Through verifications in element tests and with both small-scale and full-scale test units, MHI established the core manufacturing technology to produce the OVTs, including techniques for advanced bonding, processing, and assembling that are suitable for the properties of the materials.

Aiming to determine the practical possibilities for nuclear fusion energy, the ITER Project is an international undertaking with unprecedented technological goals. A diplomatic agreement came into effect in October 2007.

From the beginning of the ITER Project, QST and its predecessor in Japan’s nuclear fusion sector—the Japan Atomic Energy Research Institute (JAERI)—directed themselves toward R&D on the OVTs used in the diverter. MHI had first partnered with QST for their production back in 2012.

-1.png)